Introduction #

Welcome to our E Ink tutorials! We’ll start these tutorial by looking at how E Ink displays work and the displays that are available for your project.

Background #

E Ink displays were invented at MIT in the late 90s as a technology to create an electronic book. The intention was to create a display that would look just like paper, making it easy to read, unlike traditional backlit LCDs that are strenous on the eyes. Due to the way the technology works, the display also only consumes power whilst updating and as such, E Ink displays are ideal for ultra-low power applications. The main downsides being that time to update is relatively slow and that colour displays are severly limited.

How do E Ink displays work? #

E Ink displays are made from a layer of tiny microcapsules filled with a clear viscous oil and coloured charged particles. A grid of electrodes sits above and below this layer and the charged particles can be manipulated by applying an electric field across the capsules causing the charged particles to move in the direction related to their charge. Once the field is removed, the particles sit in suspension in this oil, allowing the display state to be held without requiring any power.

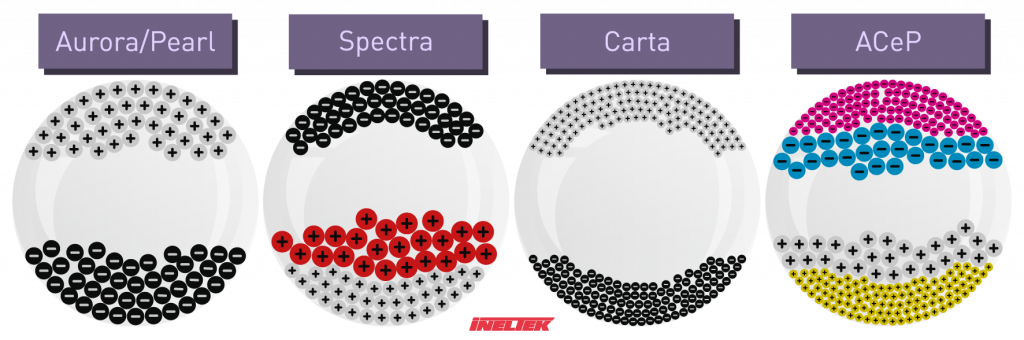

Since the original technology, E Ink has developed several more technologies that allow for higher DPI displays, 3 colour displays (black, white and red or black, white and yellow) and most recently Advanced Colour ePaper (ACeP) which allows for 4,096 colours by blending cyan, magenta, yellow and white:

E Ink vs LCD #

In it’s simplest form, a traditional LCD (liquid crystal display) works by polarising light from a light source (such as a backlight) and then using liquid crystal to alter the polarising plane before a filter either blocks or allows the light to pass through:

The liquid crystals must always have a charge applied across them otherwise they won’t stay in alignment and whilst the charge required doesn’t have to be particularly large, combined with a backlight, the current draw on LCDs tends to be fairly large.

E Ink displays on the other hand work by either reflecting or absorbing light depending on the colour of the charged particles:

However, the technology cannot produce colours as vibrant as an LCD and LCDs are also capable of refreshing at a significatly faster rate.

Types of Displays #

E Ink displays require 2 key components to work correctly, along with some volatile memory to store the display buffer and non-volatile memory to store waveform and panel information.

Timing Controller (TCON) #

The charge applied across the capsules for each pixel is determind by a waveform that controls what voltage is applied to both the top and bottom electrodes. The top electrode is always given a common voltage (known as VCOM) and the bottom electrode is given either a positive or negative voltage:

In order for this to work correctly the VCOM value must be calibrated correctly – this is done by E Ink during the manufacturing process, and a waveform must be stored in non-volatile memory to ensure the displays updates correctly at different temperatures (as the viscosity of the oil will change at different temperatures).

Power Management IC (PMIC) #

In order for the TCON to correctly update the display, it’s need several voltages to work:

- VCOM – somewhere between 0 to -5V

- 2 x positive voltages – usually between 15V and 24V

- 2 x negative voltages – usually between -15V and -24V

These voltages vary depending on the type of display, the size of the display and the type of technology.

Internal vs External Control #

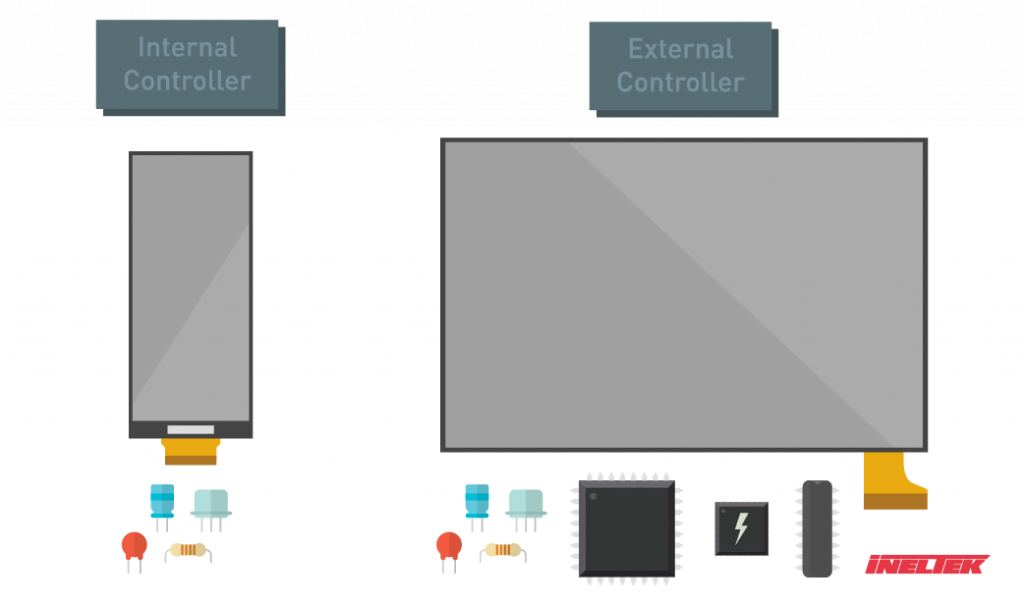

There are 2 types of E Ink displays you can buy, displays with the controller built in, known as AIO (all in one) displays and displays that have all these components external to the display.

An AIO displays only requires a power supply (usually 3.3V) and some external components for the on-board DCDC converter. There are some AIO displays that require non-volatile memory to hold the waveform file, but these are generally in the minority. An externally controller display requires a TCON, PMIC, non-volatile memory and lots of external components:

AIO displays are available in sizes from 1.1″ to 5.7″ and their capabilities in terms of colour and update speed varies. AIOs are cheaper and easier to use but are generally quite restrictive in what they can do.

Externally controlled displays can be any size (up to approx 40″) and have a lot of flexibility in their update capabilities. These displays are fast to update, allow for partial updates (instant update of the display) and can be controlled by a variety of different TCONs. However they are generally more expensive and also require external components that increase the overall cost.

At Ineltek we can support both AIO and externally controlled designs with TCON options from ITE and Epson. For more information on using E Ink for your next project – get in touch with us now.